Cleaning and Maintenance Tips for Contact Temperature Sensors: A Definitive Guide

Introduction

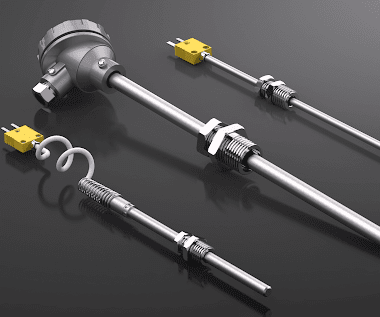

Contact temperature sensors are workhorses in many industries, from manufacturing and healthcare to food processing. While their role is crucial, their maintenance often takes a backseat. Neglected sensors can yield inaccurate results, leading to inefficiencies or even dangerous situations. This blog post aims to guide you through the best practices for cleaning and maintaining your contact temperature sensors to ensure their longevity and reliability.

Why Cleaning and Maintenance are Crucial

Accurate Readings

Residue or dirt on the sensor's surface can interfere with its ability to measure temperature correctly. Clean sensors are accurate sensors.

Longer Life-Span

Regular maintenance can significantly extend the lifespan of your sensors, saving costs in the long run.

Regulatory Compliance

In many sectors, regular cleaning and maintenance of monitoring equipment, like temperature sensors, are mandatory to comply with industry standards and regulations.

Cleaning Best Practices

Frequency

How often you should clean your sensors largely depends on their application and environment. Sensors in a cleanroom may require less frequent cleaning than those in a manufacturing plant.

Cleaning Agents

Opt for non-abrasive, non-corrosive cleaning agents. For most sensors, a gentle wipe with a cloth soaked in isopropyl alcohol can do wonders.

Method

Always turn off and unplug the sensor before cleaning. Gently wipe the sensor's surface and allow it to dry thoroughly before plugging it back in.

Maintenance Tips

Regular Calibration

In addition to cleaning, regular calibration ensures that the sensor's readings are accurate.

Visual Inspections

Look out for signs of wear and tear, particularly on the sensor's probe and cables. Frayed wires or a damaged probe require immediate replacement.

Software Updates

For sensors that come with embedded software, ensure you keep the software up-to-date to benefit from improvements and bug fixes.

When to Replace Your Sensors

Inconsistent Readings: Despite regular calibration, if the sensor shows inconsistent readings, it’s time for a replacement.

Physical Damage: Any visible damage to the sensor's probe or wiring is a surefire sign that you need a new sensor.

Outdated Technology: Sensor technology is always evolving. If your sensors are outdated, consider upgrading to take advantage of newer features and greater accuracy.

Conclusion

Cleaning and maintaining your contact temperature sensors should be a routine yet vital part of your operational practices. By ensuring that these humble but critical devices are kept in top shape, you not only guarantee the quality and safety of your products but also comply with industry standards. A small effort today can prevent significant headaches tomorrow.

Comments

Post a Comment